Engineering, architecture, automobile, manufacturing, and aerospace industries comprehensively deal with various CAD applications for preparing prototypes and final products.

Managing these files and designs is a complex process as it involves dealing with a lot of designs, along with tracking each iteration of them. Lacking a good system, even the most excellent designs will be undermined by loss of data, overwrites, or misunderstandings.

Product Data Management (PDM) systems offer the foundation for managing, storing, and keeping track of engineering data. It is crucial to ensure everyone on your team stays on the same page.

Engineers use design applications such as SolidWorks to turn ideas into reality, from complex components to massive assemblies. While SolidWorks is great for design and modeling, managing the project’s data requires a specialized solution to keep workflows seamless and data intact.

Without an effective design management tool, project teams face challenges with change management, access control, secured distribution, managing design components, collaboration, and much more.

Enginero PDM is designed to overcome these very challenges. It is not just a file management software, but an engineering-oriented, robust PDM system that brings discipline to the design process. Whether you are a small design team developing prototypes or a large engineering company managing thousands of interrelated designs, Enginero’s PDM is made to simplify, organize, and streamline your project designs.

In this article, we will discuss how Enginero PDM, a robust Product Data Management system, can streamline SolidWorks projects to make them more efficient, better organized, and collaborative. We’ll take you through the role of PDM in today’s engineering, delve into why SolidWorks users require a data management system, and demonstrate how Enginero PDM is the perfect solution for your design data management requirements.

What is Product Data Management (PDM)?

Product Data Management (PDM) is a system that enables engineering and design teams to manage, track, and organize product-related data in a smooth manner across the product development life cycle. A PDM system addresses crucial workflow and collaboration issues of teams collaborating with various CAD & BIM software.

What Problems Do PDM Solve?

- File Misplacement: There is a huge chance of misplacing the project files, as design projects involve many connected files, and retrieving them to work is a time-consuming process.

- Version Management: The project design consists of different versions for every modification and iteration. These versions are required to compare the changes and review them.

- Lack of Integration: Managing the product data, specially designs and models, requires an integration between the native design software and the data management tool in order to publish the models and track iterations.

- Collaboration with real-time updates: Usually, while working on a huge project, various team members work on the same model, which makes it difficult to share access and update the changes to the respective team members.

- Outdated Model: When multiple users work on the same design, there is a chance of dealing with an outdated model when the user forgets to update and share. This causes rework.

- File duplications: Duplicate files create confusion among designers when multiple designers work on the same project, as it creates conflicts when different designers use different models.

- Data Storage and Access: Storage in a dedicated project repository and securing it by providing limited and controlled access to the project team members is difficult without a PDM system.

The Role of PDM in Modern Engineering:

With the increase in customer requirements, there need involvement of various teams along with the core departments and their project data. This involves working with assorted designs, products, and components collaboratively, without losing the data and securing the product integrity.

Product Data Management (PDM) systems work as a backbone to modern engineering projects. This ensures every piece of product data, whether it is 3D models, 2D drawings, Bill of materials, design properties, or component information, all secured and managed under one platform for the complete product lifecycle.

PDM systems proactively structure and manage this data, providing version control, access controls, workflow automation, and complete traceability. This not only avoids the possibility of outdated files but also enables compliant and consistent engineering practices.

Modern engineering relies on collaboration. PDM facilitates more effective communication across departments, engineering, manufacturing, and quality, ensuring they are all on the same page and drawing from the same source of truth.

In today’s digital world, PDM is not merely useful; it is crucial. From streamlining design cycles to time-to-market acceleration and compliance with stringent regulatory requirements, the PDM role in contemporary engineering is both strategic and transformative.

Enhancing Project Efficiency in SolidWorks Through Intelligent PDM:

SolidWorks is a versatile computer-aided design software platform used across various industries to create detailed designs for their products, from simple part designs to massive assemblies and complex component designs.

As the projects go beyond, when the necessity and scope grow, it becomes challenging for the project management teams and designers, especially while collaborating cross-departmentally and involving multiple designers.

Teams often struggle with version conflicts, miscommunication, and fragmented workflows. Apart from this, there is a chance that files could be overwritten or misplaced, and cross-referenced elements in design across various products can create confusion if not carefully managed.

Tackle these concerns, SolidWorks users need a robust and customized product data management platform that resolves the SolidWorks product management problems seamlessly. Enginero offers a comprehensive product data management platform for managing all your product files and designs related to SolidWorks effectively.

Enginero PDM: Empowering Collaborative Product Development in SolidWorks

Designers, project managers, and engineers frequently work together across departments, sometimes across the globe. Within this context, SolidWorks users require more than file storage. They require something that can manage advanced dependencies, provide real-time access, and facilitate multi-user workflows seamlessly.

Enginero helps mitigate these conflicts by providing an advanced product data management tool for SolidWorks designers, providing a centralized cloud environment to store, manage, and connect with multiple designers for the complete product life cycle.

Regardless of whether your teams are creating parts for a standalone product or working on multiple projects with common components, Enginero keeps everyone working on the right version, with complete visibility into the status of the project. Let us have a look at the few outstanding features of Enginero’s SolidWorks PDM.

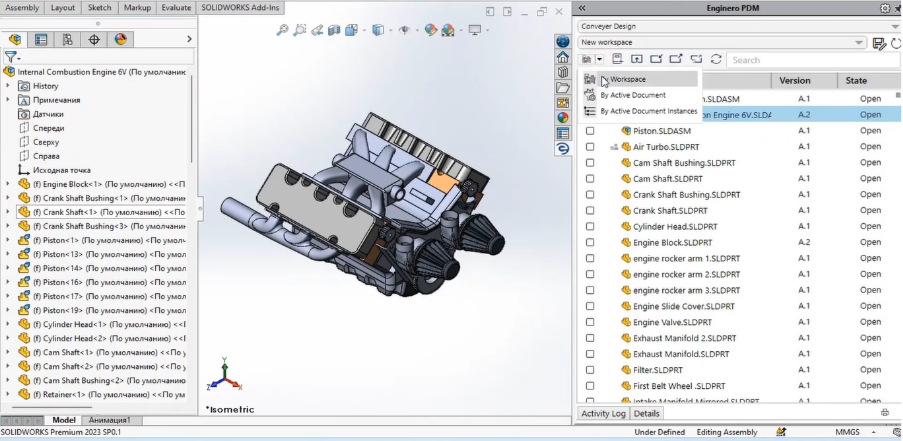

Direct Integration with SolidWorks:

Enginero’s PDM comes with a customized plugin that directly integrates your native SolidWorks application to the PDM platform. This helps project users to upload the SolidWorks models directly with no interference.

Also, Enginero users can open any SolidWorks design associated with the project directly from the cloud and work from their native computer systems. After every iteration, users can update the design from SolidWorks, making every iteration updated while maintaining transparency.

Version Tracking:

Enginero PDM tracks every iteration and creates them as a version of the respective design, providing the exact timestamp along with the date of modification. This feature helps you track the evolution of your design over time, ensuring full traceability and accountability for every change made.

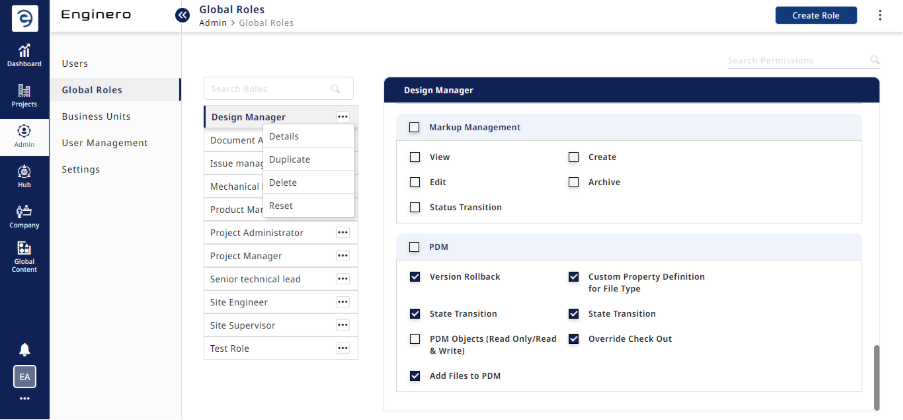

Role-based Permission Management:

Data integrity is key in any design project. With Enginero, you can ensure that the right person has access to the respective files, design, or actions. From the start of the project, you can create custom roles with desired permissions and assign the role to the respective user.

Also, users’ roles could be changed as per the project requirements. Enginero prevents the unauthorized viewing, editing, or approval of designs, mitigating the chances of unauthorized alteration or data loss. Every action taken by users is traced, ensuring an open trail of activities for accountability and facilitating audits or design reviews.

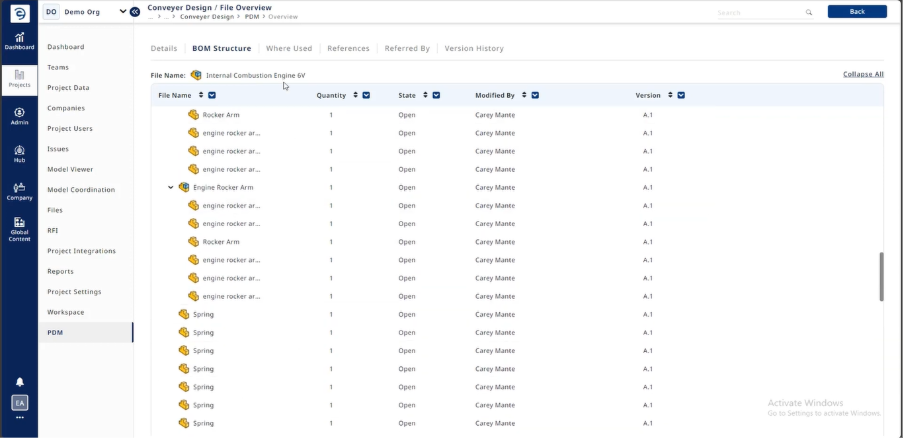

Bill of Materials (BOM) management:

Once a product’s design is uploaded, a simplified bill of all the components, sub-assemblies, and parts is displayed as per the model hierarchy developed in SolidWorks. The user can open each of the BOMs and visualize them whenever needed.

Customized Product Workflows:

Enginero PDM allows its users to create workflows for every design product along with customized stages. For every workflow, stages like work-in-progress, under approval, started, completed, and many customized states can be defined.

Each stage within the workflow will have predetermined rules, tasks, and approvals to ensure that actions flow well throughout the pipeline with no hindrance. Alerts and status reports update team members on a real-time basis, lowering miscommunication and delays.

Document Control Mechanism:

Enginero PDM has unique features to access the SolidWorks files. Work with a file, the user has to check out, which assigns the ownership to the checked-out user and provides access to modify. Check out also restricts other users from accessing it, making users wait until the file is checked back in, thus preventing conflicts or overwrites.

After modifications, the user has to check in to update the changes, and Enginero automatically creates a version of the document with the respective timestamp. Then, this gives other users a chance to work on the updated version of the design file.

This feature offers a transparent record of file history and ownership, allowing users to manage file versions and collaboration directly within their CAD environment.

Enginero PDM does not just manage data; it actively enables better teamwork. By streamlining collaboration in SolidWorks, it transforms how engineering teams design, revise, and deliver high-quality products faster and more efficiently.

Conclusion:

In the realm of fast-paced modern engineering, efficient and secure data management is not something you can negotiate. SolidWorks is one of the most used CAD applications, yet an improper design data management system leaves teams vulnerable to conflating versions, losing data, and delays. Enginero PDM helps in managing designs for the whole product lifecycle.

With high-end features and secure document control, Enginero PDM revolutionizes the landscape for engineering teams in managing and collaborating on projects.

The streamlined product data management of SolidWorks by Enginero allows teams to innovate faster, collaborate smarter, and deliver remarkable results with confidence.

Ready to take control of your engineering data? Visit www.enginero.com to schedule a free demo or start your trial!

Leave a Reply